Difference between revisions of "Atlas Lathe Restoration"

| (8 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | This is an Atlas | + | This is an Atlas TH42 lathe made by the Atlas Press Company, made at the Kalamazoo Michigan plant. The model number indicates it was made after 1947, has roller-bearings in the head-stock, and uses changewheel screwcutting. It has a 42 inch bed with 30" capacity between the centers. More info on Atlas lathes is available here: [http://www.lathes.co.uk/atlas/ http://www.lathes.co.uk/atlas/]. I inherited this from my Great Uncle Wilfred. He was concerned about his shop tools going to good use after he left us, I think this one will go to very good use. |

| Line 11: | Line 11: | ||

{| | {| | ||

| − | | [[Image:IMG_0565.JPG|none|thumb|200px|Drive | + | | [[Image:IMG_0565.JPG|none|thumb|200px|Drive pulleys]] |

| [[Image:IMG_0567.JPG|none|thumb|150px|An old repair]] | | [[Image:IMG_0567.JPG|none|thumb|150px|An old repair]] | ||

| [[Image:IMG_0569.JPG|none|thumb|200px|Box of lathe tools]] | | [[Image:IMG_0569.JPG|none|thumb|200px|Box of lathe tools]] | ||

| Line 23: | Line 23: | ||

==Electrolysis rust removal== | ==Electrolysis rust removal== | ||

| − | In order to facilitate major rust removal, we built an [[Electrolysis_Rust_Removal_System]]. Simply leave the part in the bucket of solution for 24 hours with voltage applied and out comes clean parts. Amazing! Here are some of the early results, compare to the very first photo at the top of this page | + | In order to facilitate major rust removal, we built an [[Electrolysis_Rust_Removal_System]]. Simply leave the part in the bucket of solution for 24 hours with voltage applied and out comes clean parts. Amazing! Here are some of the early results, compare to the very first photo at the top of this page. Also notice the tailstock center, the rust is removed but the missing metal can't be helped - but you can read the indicators on the shaft now. |

| − | [[Image:Rust_03.jpg|none|thumb|200px|Rust gone from chuck]] | + | {| |

| + | | [[Image:Rust_03.jpg|none|thumb|200px|Rust gone from chuck]] | ||

| + | | [[Image:IMG_0644.JPG|none|thumb|200px|Tailstock cleaned up]] | ||

| + | | [[Image:IMG_0607.JPG|none|thumb|200px|Before: tailstock center, dial indicator, and thread counter]] | ||

| + | | [[Image:IMG_0642.JPG|none|thumb|200px|After: tailstock center]] | ||

| + | |} | ||

| + | |||

| + | [[Image:IMG_0701.JPG|none|thumb|200px|After: cross-slide components]] | ||

| + | |||

| + | |||

| + | == Getting it running == | ||

| + | This project fell onto the back burner for a while but it has finally come to completion. I acquired a heavy duty WWII-era table off craigslist which is large enough to properly support the lathe. I picked up a Power-twist V-belt and an EPO switch from Amazon as finishing touches and we're up and running. | ||

| + | |||

| + | |||

| + | |||

| + | {| | ||

| + | | [[Image:IMG_2281.JPG|none|thumb|200px|Getting bolted to the table]] | ||

| + | | [[Image:IMG_2395.JPG|none|thumb|200px|Lathe in working order]] | ||

| + | | [[Image:IMG_2388.JPG|none|thumb|200px|Turning aluminum]] | ||

| + | | [[Image:IMG_2396b.JPG|none|thumb|150px|Glory shot of the tools]] | ||

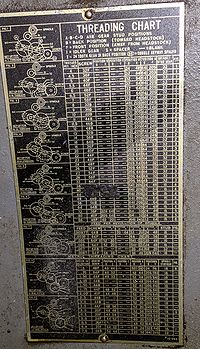

| + | | [[File:Thread_chart.jpg|none|thumb|200px|Thread Chart on Head stock cover ]] | ||

| + | |} | ||

| + | |||

| + | [[Category:dosman projects]] | ||

| + | [[Category: Tools]] | ||

Latest revision as of 14:49, 11 August 2021

This is an Atlas TH42 lathe made by the Atlas Press Company, made at the Kalamazoo Michigan plant. The model number indicates it was made after 1947, has roller-bearings in the head-stock, and uses changewheel screwcutting. It has a 42 inch bed with 30" capacity between the centers. More info on Atlas lathes is available here: http://www.lathes.co.uk/atlas/. I inherited this from my Great Uncle Wilfred. He was concerned about his shop tools going to good use after he left us, I think this one will go to very good use.

Contents |

[edit] Original condition

[edit] Initial cleanup

A couple folks immediately took to the lathe with a wire brush and some 3-in-1 oil:

[edit] Electrolysis rust removal

In order to facilitate major rust removal, we built an Electrolysis_Rust_Removal_System. Simply leave the part in the bucket of solution for 24 hours with voltage applied and out comes clean parts. Amazing! Here are some of the early results, compare to the very first photo at the top of this page. Also notice the tailstock center, the rust is removed but the missing metal can't be helped - but you can read the indicators on the shaft now.

[edit] Getting it running

This project fell onto the back burner for a while but it has finally come to completion. I acquired a heavy duty WWII-era table off craigslist which is large enough to properly support the lathe. I picked up a Power-twist V-belt and an EPO switch from Amazon as finishing touches and we're up and running.